In solid fuel power plants, the condition of the bed is essential to ensure efficiency and usability.

Sintered sand, metals and large quantities of stones cause not only uneven combustion and emissions but also, in the worst case, blockage of the entire bed.

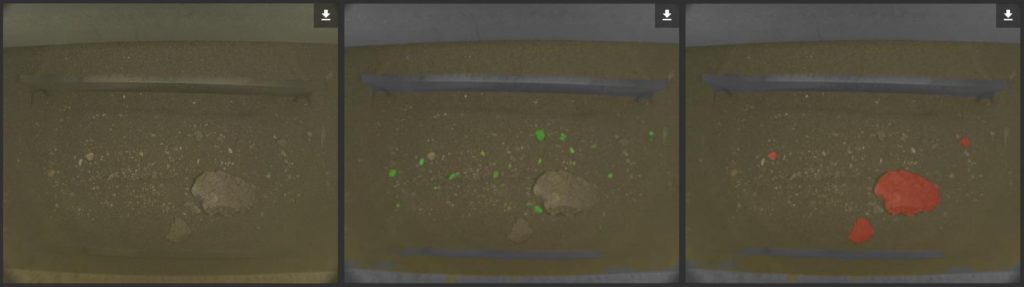

The condition of the bed can be monitored easily with the help of a camera installed on the conveyor line and a machine vision model. The analysis results can be used to optimize the amount of sand to be exchanged and detect possible sintering.

Analysis results can be imported directly into the automation system for control room alarms.