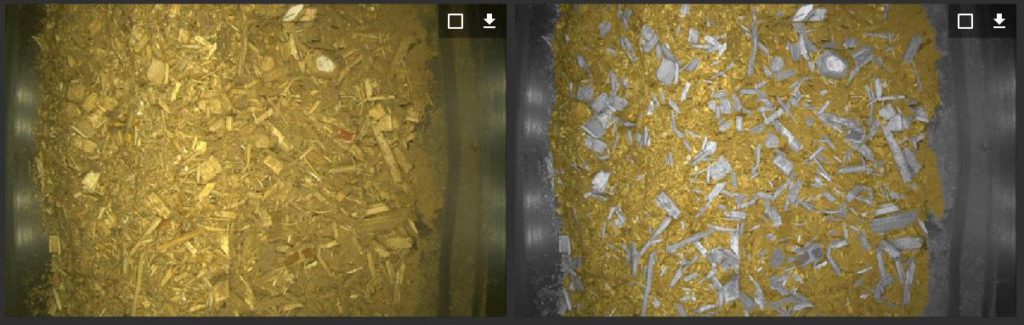

Operation of solid fuel boilers is highly dependent on what material is being burned and what is the composition of the material. The quality of the fuel usually fluctuates between different sources and the different fuel qualities get mixed before being fed into the boiler. When a camera is installed to monitor the feed conveyor of the boiler it is possible to monitor the properties of the fuel.

It is often difficult to determine the cause for changes in the boiler operations. Changes may be caused by issues in the equipment or simply because the fuel quality has changed. Computer vision makes it possible to connect changes in operations to changes in fuel and hence it enables realtime boiler optimization. Additionally supplier quality can be easily monitored.

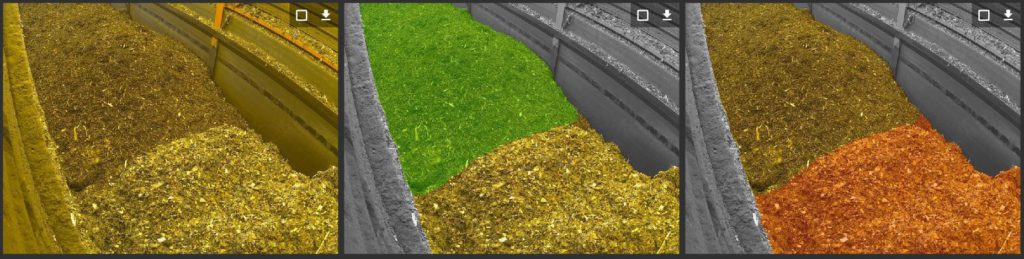

Better fuel quality control can alternatively be achieved by silo arrangements or by investing info fuel sampling equipment. The benefit of computer vision compared to the alternatives is the significantly lower investment cost and capability to flexibly optimize operations on a continuous basis.

A specific issue on bio-based boilers is the high content of small particle size material in the fuel. With computer vision these issues can be tackled by well-timed adjustment of the boiler parameters.