Conveyor condition monitoring

Machine vision is well suited to monitor the condition of mechanical equipment in areas where sensory monitoring would be difficult or laborious. An example of condition monitoring can be found at Pori Energia's power plant, where continuous monitoring of critical equipment helps ensure the plant's availability.

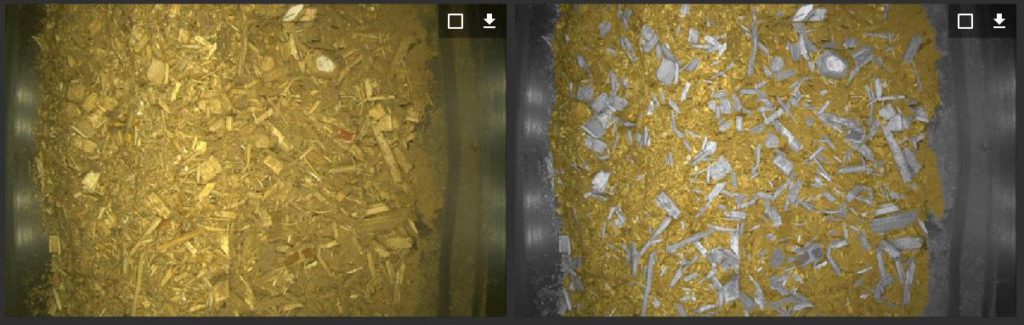

Industrial fuel material classification

Operation of solid fuel boilers is highly dendent on what fuel is being burned what the is the composition of the material. With computer vision fuel quality can be monitored in real time.

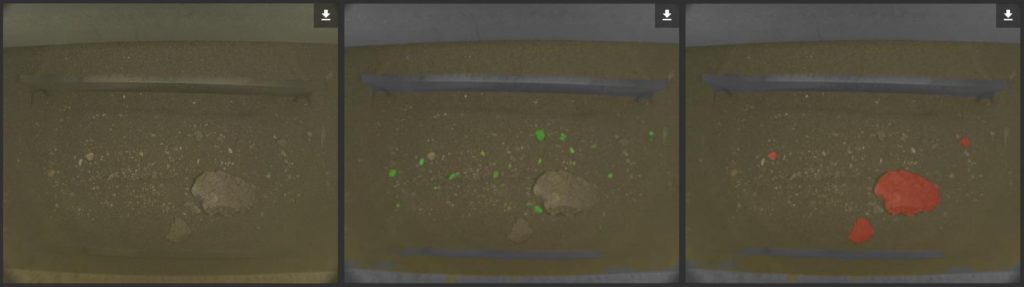

Power plant ash analysis

The ash or bed material quality is essential for solid fuel boilers. Computer vision models enable real time analysis of foreign material and agglomerates ash.

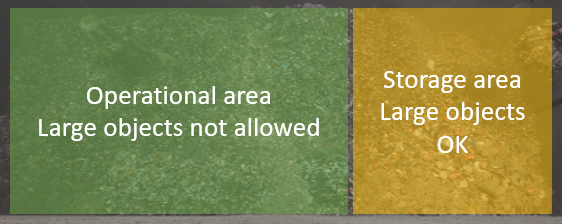

Waste bunker large objects control

Debarking monitoring

In practice the optimization of debarking is set up by installing two cameras on the line:The main after the debarking drum will monitor the main product and secondary camera on the bark line to monitor the composition of the removed material. The main camera’s goal is to ensure no bark is left on the wood. The secondary camera ensures that the bark flow contains as little fiber wood as possible.

Preselection of user images

Want to find out more or play around with you ideas. Contact.